NORDLOCK

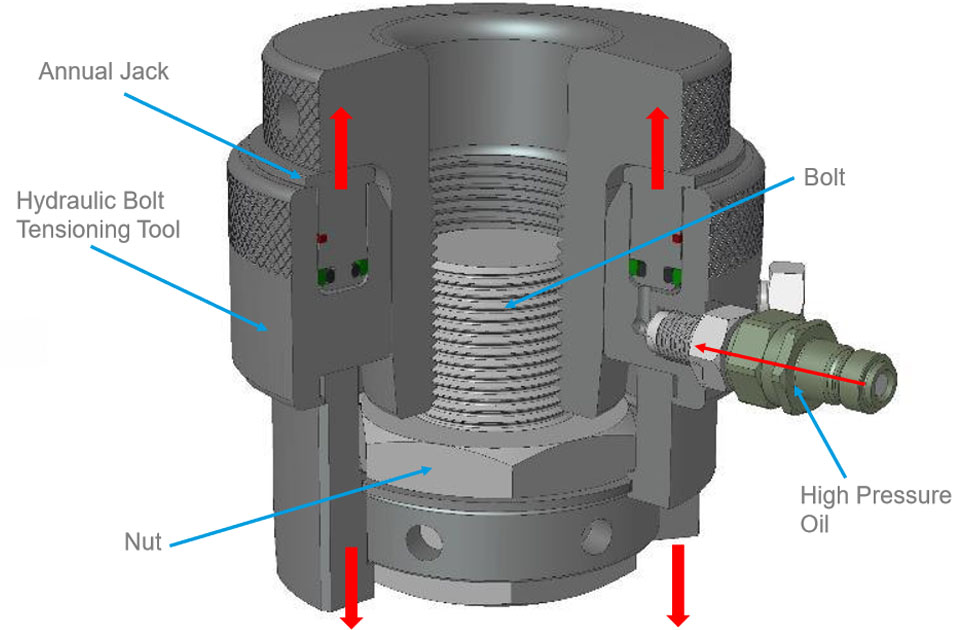

Standard 1500 bar Topside Range -Features

- 1500 bar MWP

- 15mm stroke

- Profiling for weight saving

- Quick Release Bridge

- Single or Twin Port options

- Extremely Durable due to surface coating of components (Nitride)

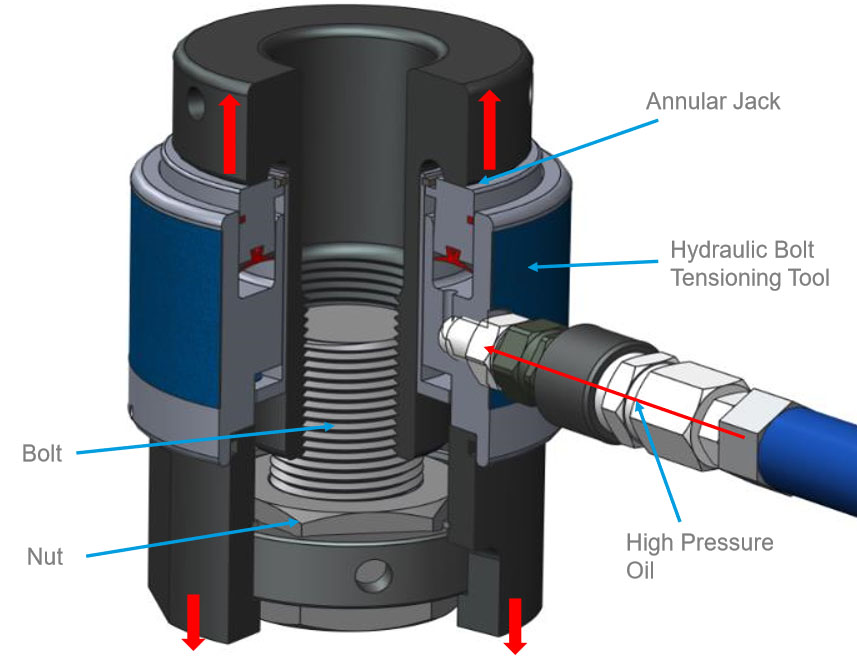

TSR Spring Return Range -Features

- 1500 bar MWP

- 10mm stroke (except TSR0 – 8mm)

- Spring assisted return

- Safety relief valve to protect seals from overstroke

- Profiling for weight saving

- Component Interfaces (Puller lead in, etc.)

- Swivel Connection Available

- Held in stock

Xtra Range Features

- Compact Flanges

- 1500 bar

- 15mm stroke

- Higher Load output

- Profiling for weight saving

- Direct fit reduces weight and tool OD

- Spring Return Optional

- Long Life Composite Seals

- Few competitors have an equivalent

Subsea Tensioners Features

- Solid or split reaction nuts

- Corrosion resistant finish

- Specials available

- Integrated body and bridge

Multi Stage Typhoon Tensioner –Features

- Designed for high loads – up to 95% yield stress for 10.9 bolts

- Small footprint -Suitable for tight spaces between bolts

- Higher cycle / fatigue life than most competition

- Spring return

- Durable coating on all components

- Joint misalignment compensation features

- Internal fail safe mechanism

- Manifold safety handle (optional)

- Cycle counter (optional)

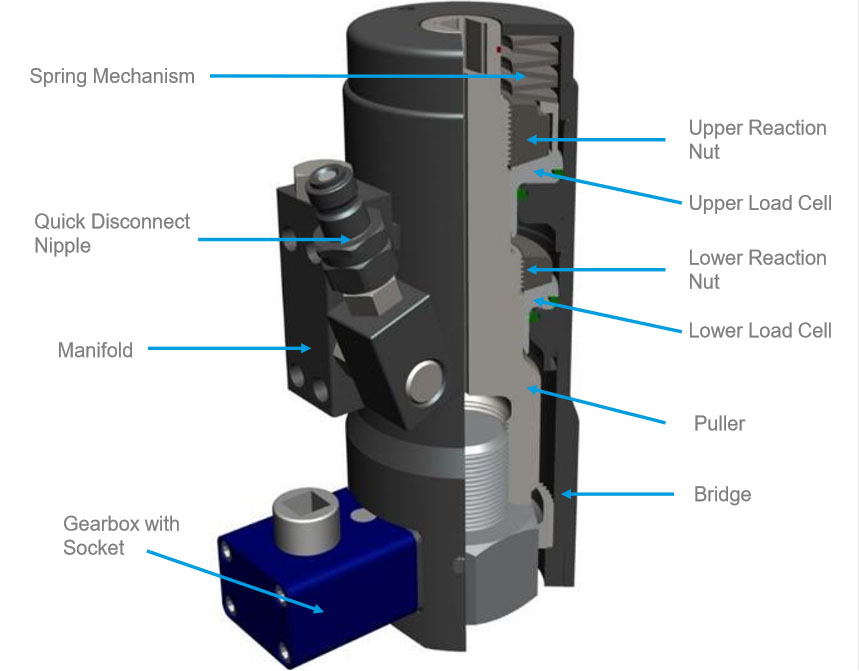

Foundation Tool Features

- 1500 bar

- Common to many bolt sizes

- Economy (customer nut) and split nut types also available

- Spring return, gearbox, positive stop etc available as options

Multi Stud Tensioners

- Application specific designs

- Offers time savings over individual tools (important for Nuclear industry, Subsea)

- Additional functionality available:

- Spring retraction

- Gear driven sockets

- Positive stop

- Higher load / compact designs

- Increased stroke

The innovative EzFit expansion sleeve coupling bolt from Superbolt lets you replace large fitted or interference-fit bolts without modifying your equipment.

How it works

- The mechanical tensioner at the small end of the taper stud (side A) pulls the stud into the expanding split sleeve for radial preloading.

- The split sleeve expands and exerts a large radial force into the bores of the coupling bolt holes to give a truly fitted bolt.

- The mechanical tensioner at the large end of the taper stud (side B) provides the axial clamping forces.

- In removal, the large end tensioner (side B) is used to pull the stud out of the sleeve, which then collapses for easy withdrawal from the hole.

The Expander System is ideal for construction, mining and forestry machinery and is by far the simplest and most economical way to resolve the problems with worn pivot lugs. Expander System is an easy, fast and permanent solution to lug wear.

Expander provides an advanced, cost-effective solution that prevents lug wear once and for all. With our Expander System Online, our engineers can customize designs quickly for new applications. Thanks to our two manufacturing sites, Åtvidaberg Sweden and DeWitt Iowa USA, we have high availability worldwide. Our production facilities are prepared to meet your needs whether it is a single piece order or a large volume blanket order. As part of the Nord-Lock Group we can offer local service and support through our representatives around the world.

The Nord-Lock Group focuses on solving the toughest challenges for bolted joints. We offer a unique combination of expertise on bolted joints and a broad range of products – all constructed and developed in-house.

Nord-Lock washers are easy and effective to use while ensuring structural security for applications exposed to vibration and dynamic loads.

Installing the washers

The pre-assembled washers are installed in pairs, cam face to cam face. Nord-Lock recommends lubrication when possible.

Tightening

Tighten Nord-Lock washers with standard tools according to the guidelines (on page 9-11). Tightening guidelines for other bolt grades are available through your Nord-Lock representative.

Untightening

Untightening Nord-Lock washers is as simple as tightening. Note that since the locking function is not based on increased friction, the untightening torque is generally lower than the tightening torque. Therefore it is not possible to measure offtorque as verification of locking function.

Reusing Nord-Lock

Nord-Lock washers can normally be reused. As with all fasteners, they should be inspected for wear before reassembly. Make sure that the washers are reinstalled correctly cam face to cam face. Nord-Lock recommends lubrication of fasteners before reuse in order to minimize changes in friction conditions.

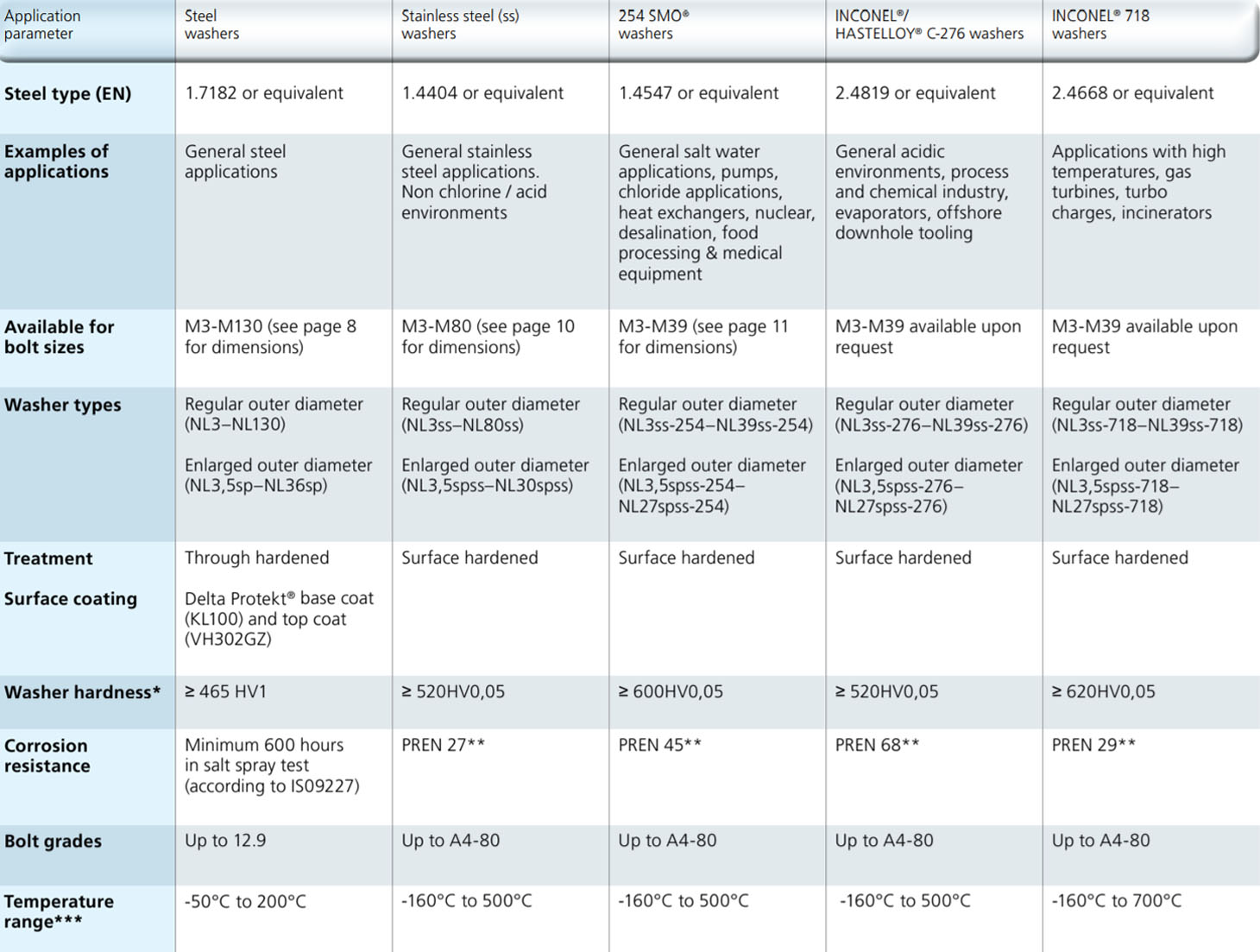

Nord-Lock washer material / type guide

Nord-Lock steel washers

Superbolt tensioners are designed as direct replacements for conventional nuts and bolts. These devices can be threaded onto a new or existing bolt, stud, threaded rod or shaft. The main thread serves to position the tensioner on the bolt or stud against the hardened washer and the load bearing surface.

Once it is positioned, actual tensioning of the bolt or stud is accomplished with simple hand tools by torquing the jackbolts which encircle the main thread. The jackbolts transfer the preload evenly into the main thread and, consequently, onto the joint. The main thread is tightened in pure tension.

How Superbolt tensioners work:

- By tightening the jackbolts, a strong thrust (axial) force is generated. This thrust force is directed against a hardened washer. Jackbolts have a small friction diameter and can therefore create a high thrust force with relatively little torque input.

- The loads are transferred through the nut body which is positioned on the main thread by hand.

- A hardened washer is used to transfer the force while protecting the flange face.

- The thrust (axial) force of many jackbolts and the opposite reaction force of the main bolt head create a strong clamping force on the flange.

- The thrust (axial) force from the jackbolt creates an equally strong reaction force in the main bolt.

Selection Guide

TORQLITE USA

A time tested and proven tool design, square drive ratchets offer a cost efficient option to handle a wide range of bolting make-up and break-out needs. The SU-XL Series ratchet employs a “patented design”, which increases accuracy and reduces the number of moving parts. TL T-6 XL Series body encloses the drive train assembly, allowing no pinch points and lighter weight. Our standard SU-XL Series tool capacities range from 100 to 60,000 foot pounds of torque using a 10,000 p.s.i. hydraulic pump.